01Tool Lading

The slitting machine cutter masters typesetting the cutter according to the specification and size of the processing document, adjusts the clearance between the cutters, and ensures that the material is qualified with burrs.

The slitting machine cutter masters typesetting the cutter according to the specification and size of the processing document, adjusts the clearance between the cutters, and ensures that the material is qualified with burrs.

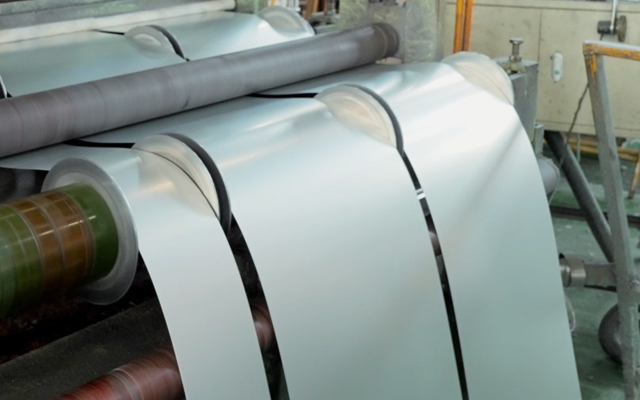

The main control captain of the slitting line confirms that the whole line is ready, presses the linkage control switch of the whole machine, and controls the whole machine to accelerate slowly at a constant speed to achieve the slitting speed suitable for the current material. When the material slitting is about to reach the end, control the Slowly decelerate the machine at a constant speed. Until the material slitting process is completed.

During the start-up of the entire cross-cutting unit and the automatic production process, the flatness of the raw material itself and the rolls is lacking. After manually adjusting the leveling auxiliary stick, it can be adjusted at any time to ensure that the flatness of the material reaches the standard.

In the whole roll of steel processing process, the quality inspector should re-measure the material according to the data of the processing order, and measure the thickness of the plate head, plate middle and plate tail of the whole coil and record it in the book for later quality tracking and review.

After comparing the requirements of the processing documents, input the cutting size in the main control computer, cut the steel plate, and manually double-scale the cut steel plate to ensure the accurate size and the dimensional tolerance of the two diagonal corners of the cut steel plate. within normal tolerances.

Under the light, it is easier to find various surface problems from raw materials, burrs and iron powder friction after slitting, and it can be stopped in time.

The cut steel plate is fully enclosed with anti-rust paper to prevent quality problems such as rusting caused by direct contact with the steel plate by the moist air. The material and the wooden support are fixed with three horizontal and one vertical with steel belts to ensure the safety of hoisting and transportation.